Instrumentation Screened Cables

Product Details:

Instrumentation Screened Cables Price And Quantity

- 50 Meter

- 200 INR/Meter

Instrumentation Screened Cables Trade Information

- 1000 Meter Per Day

- 1-7 Days

- All India

Product Description

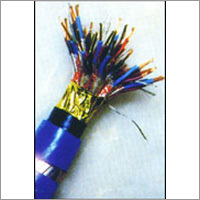

Instrumentation Screened Cables

Find application in power generation and distribution, the offered Instrumentation Screened Cables are known for their high endurance and sturdy construction. These cables are manufactured by making use of supreme quality raw materials and innovative techniques at our well-equipped production unit. Our quality analysts check the provided cables on several parameters of quality before delivering at clients' end. In addition, we offer these Instrumentation Screened Cables in different thicknesses and lengths at industry leading rates.

Key Features:

- Excellent finish

- Optimum physical and electrical property

- High strength

- Flexibility

The series of Instrumentation Screened Cables offered by us are ideal for signal transmission and process control. These cables are very important for safekeeping of various factors like productivity, quality, cost and control of complete plant. The said plant can be of any industry such as Aluminum Plants, Fertilizers, Oil Refineries, Petrochemical, Power Generation & Distribution, Steel Plants and Other Engineering Industries.

The Instrumentation Screened Cables are shielded or screened using aluminum-mylar tape with tinned copper braided or copper drain wire. Each type of shielding has it's own benefits and the type of shielding depends solely on the type of application. For low signal speed, braid screen is enough; but for high signal speed, it is better to use a composite foil or foiled screen & braid screen. An additional feature is to use individually screened pairs for decreasing the effects of 'cross talk', hence allowing the data transmission over long distances. The Instrumentation Screened Cables are protected from mechanical stress with the armoring of Flat Strip / Flexible Braiding / Galvanized Steel Wire.

The shielding is done for the prevention of harmful electrostatic interference. The top 3 reasons / benefits of electrostatic shielding in the screened cables are as follows:

- External electrical disturbances do not affect the cable signal.

- The cable signal is NOT Detectable, except at the ends of cable.

- Cross talk : Elimination of non-important and abdicable signal transfer amidst the circuit of same cable.

Contact Us

Contact Us Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free